The use of imaging technology in industrial inspection has changed substantially over the years. Traditionally, manual inspection dominated quality control, which meant manufacturers were relying heavily on human effort to assess product defects, misalignments, or other issues.

Thankfully, the emergence of embedded vision technology, along with advancements in sensor technology, optics, and machine learning, made industrial inspection systems smarter, faster, and more intuitive. As time progressed, they became capable of detecting even the most subtle irregularities in production environments. Hence, considering these systems must operate continuously and deliver accurate results, the importance of finding the right camera is extremely important.

In this blog, you’ll get expert insights on industrial inspection systems, the use cases they cover, and the must-have features that must find their way into their cameras.

What is an Industrial Inspection Camera?

An industrial inspection camera is used to visually examine and inspect products or components during the manufacturing process. It captures high-resolution images or video to detect defects, measure dimensions, and verify the quality of parts in real time. These cameras are integral to automated quality control systems across several industries.

Moreover, these cameras provide uniform and objective evaluations compared to human inspectors, eliminating the risk of human error. After all, the need for consistent quality in mass production cannot be overstated. Whether detecting cracks, measuring dimensions, or verifying alignment, industrial inspection cameras make sure the products meet the required standards.

In a world where consumer expectations are high and regulatory compliance is stringent, this can be necessary to maintaining high-quality output while preventing costly recalls or defects.

Where Are Industrial Inspection Cameras Used?

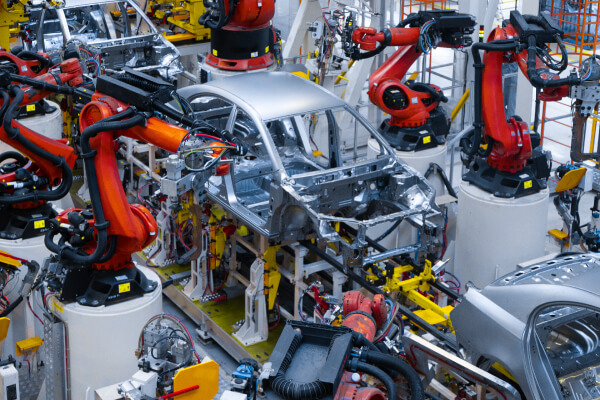

- Manufacturing and assembly line inspection: Cameras ensure real-time product monitoring, identifying any deviations from the standard. In automotive manufacturing, cameras can check for scratches, improper assembly, or faulty components, preventing defects from reaching consumers.

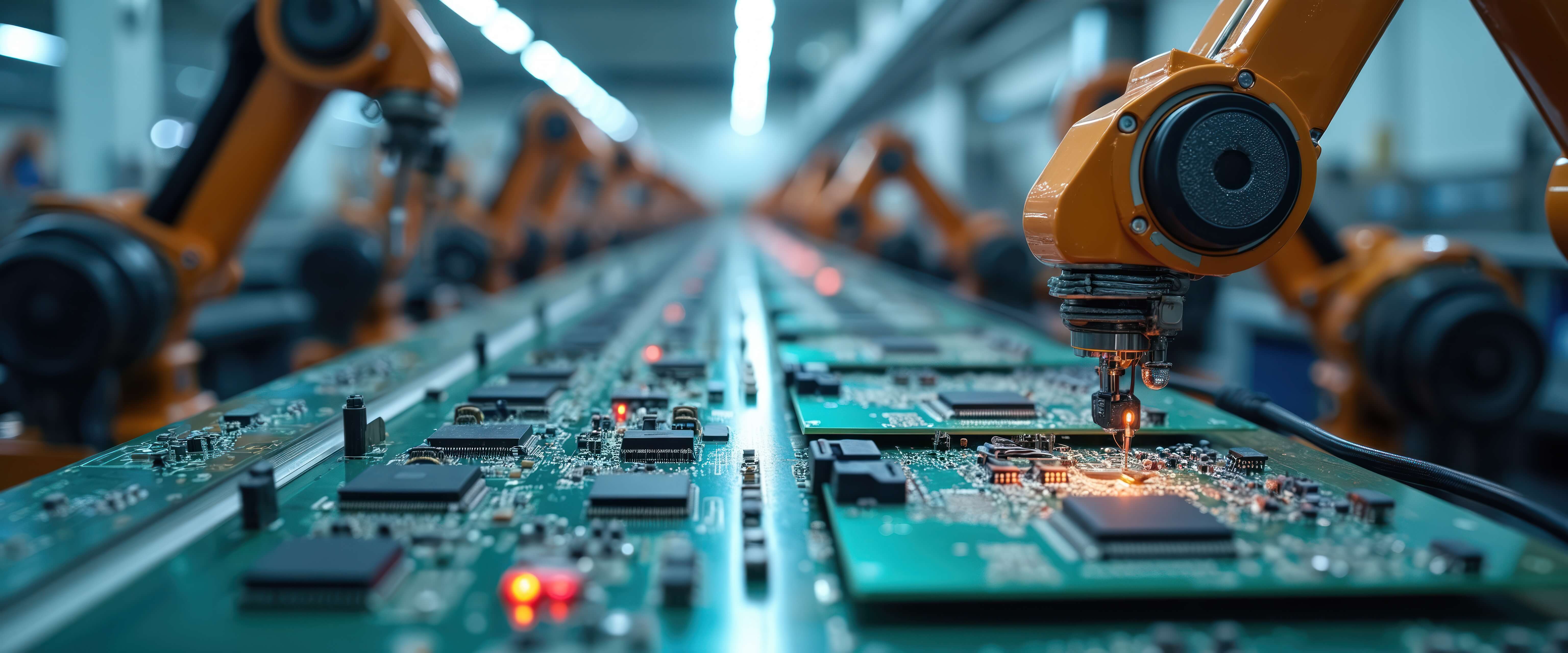

- Electronics and semiconductor production: In semiconductor manufacturing, inspection cameras are leveraged to detect even the smallest irregularities in circuit boards and microchips. Their high-resolution feature enables the identification of finer details (such as soldering defects or alignment problems.

- Industrial automation: In automated drilling processes, inspection cameras offer real-time feedback to monitor drill positioning, as well as depth accuracy and wear detection. These cameras are integrated with control systems to help optimize drilling precision and reduce material wastage.

- Pharmaceuticals and medical devices: Inspection cameras monitor the production of medicines, ensuring proper labeling, packaging, and absence of contaminants. Similarly, for medical devices, cameras verify that each component meets stringent quality and safety standards.

- Food and beverages: In this sector, inspection cameras are used to detect contaminants, verify packaging integrity, and confirm product labeling. They also help make sure that the contents are correctly placed and within weight tolerances.

- Printing and packaging: Inspection cameras ensure that printing and packaging are done accurately. So, they can detect misprints, incorrect labeling, or poor alignment in packaging materials, ensuring that branding and information are correctly displayed.

Key Camera Features of Industrial Inspection Systems

High frame rates

In manufacturing, objects tend to move rapidly along assembly lines, which is why cameras with high frame rates are absolutely necessary. These cameras capture a high number of frames per second, enabling the system to freeze fast-moving objects for a detailed inspection. In cases where high-speed processes are involved, such as monitoring product alignment on a conveyor belt, missing even a fraction of a second could mean defects go unnoticed.

High frame rate cameras provide the level of detail needed to inspect each product carefully, regardless of the speed at which they move through the system. For instance, these cameras can capture the motion of car parts on assembly lines, inspecting for alignment issues or irregularities that would be impossible for the human eye to detect in real time.

Global shutter

Unlike rolling shutter cameras, which capture an image in sequential strips, global shutter cameras capture the entire image simultaneously, which eliminates motion distortion. It is important for industrial scenarios where even slight distortions can cause significant quality issues.

For example, in high-speed bottle filling lines, a rolling shutter could distort the image of moving bottles, making it difficult to spot issues like improper filling or cap misalignment. Global shutters, however, ensure that each image is clear and undistorted, no matter how fast the product is moving.

High resolution

High-resolution cameras are very useful when even the smallest defects could have major consequences. These cameras capture images with fine detail, which is a must-have feature in manufacturing, as components may be measured in micrometers.

A camera with insufficient resolution can miss flaws (like a microscopic crack in a silicon wafer) which can result in defective products reaching the market. Catching these defects early helps prevent costly repairs or even potential safety issues down the line.

Low-light performance

Industrial environments do not always provide optimal lighting conditions for inspection processes. Many facilities, especially in warehousing or logistics, have uneven lighting or operate in dim conditions. Cameras equipped with low-light capabilities are able to maintain image clarity even in these challenging settings.

For instance, in a large warehouse where quality control of packaged goods occurs, low-light cameras ensure that every item is thoroughly inspected, even in shadowed areas. It reduces the chance of defective products slipping through the process due to poor lighting conditions.

Edge device compatibility

As industrial environments increasingly move toward edge computing, cameras compatible with edge devices are becoming a key component in inspection systems. They process data closer to the source, reducing the need to transfer large volumes of information to centralized servers. Such local processing capability helps reduce bandwidth usage, minimizes latency, and provides faster responses in time-critical applications like assembly line monitoring.

Low latency

Cameras with low-latency performance minimize delays between image capture and data processing, allowing for instant corrective actions when a defect is detected. In scenarios such as robotic assembly or automated manufacturing, even a minor delay can result in costly production errors or material waste. Low-latency cameras are also engineered to provide rapid data transmission, ensuring smooth integration with control systems and driving real-time quality control.

Durability

Inspection cameras in industrial settings must withstand harsh conditions, including exposure to dust, extreme temperatures, humidity, and constant vibrations. These cameras are typically built with rugged housings and protective features to ensure longevity and reliable performance under demanding conditions. Let’s take the case of oil and gas or mining, where equipment is exposed to dust and dirt. A durable camera ensures that inspections can continue without frequent maintenance or risk of damage.

e-con Systems’ Cameras for Industrial Inspection Systems

Since 2003, e-con Systems has been designing, developing, and manufacturing OEM cameras. We provide a wide range of camera products that meet the modern demands of quality inspection systems. We also have customizable lens options to address various Field-of-View and focus requirements. Our USB cameras can integrate seamlessly into existing industrial and inspection systems, ensuring easy deployment and faster go-to-market.

For more rugged use cases, e-con Systems provides GMSL cable connections, supporting distances of 10m to 15m from the host. The cameras are compatible with NVIDIA Jetson platforms, with production-ready drivers and multi-camera synchronization capabilities, thereby enhancing functionality in complex inspection setups.

Explore our Camera Selector page for a full view of all our cameras.

If you need an expert to help integrate the perfect camera into industrial inspection system, please write to camerasolutions@e-consystems.com.

Suresh Madhu is the product marketing manager with 16+ years of experience in embedded product design, technical architecture, SOM product design, camera solutions, and product development. He has played an integral part in helping many customers build their products by integrating the right vision technology into them.