As you may know, the camera does not perceive brightness in a linear manner. Instead, it is sensitive to changes in brightness in darker areas than in brighter areas.

Gamma correction compensates for the relationship between a pixel’s numerical value and its actual luminance. This compensation is important to ensure that images appear correctly in the camera, taking into account the non-linear perception of brightness. In this blog, let’s look at the components of how gamma correction works, why it’s important for embedded vision systems, and the challenges associated with it.

Key components of gamma correction

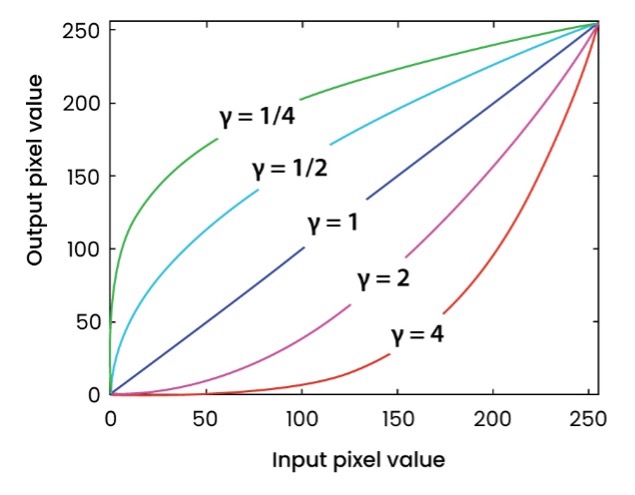

- Gamma value:The gamma correction process involves applying a specific mathematical function to the intensity values of an image. It is represented by a gamma value (γ), typically between 1.8 and 2.5 for various applications. The gamma value influences the shape of the correction curve.

- Gamma encoding:Gamma correction involves applying a gamma function to the numerical pixel values. Then, it transforms them into a non-linear representation that better matches the camera’s perception. The encoding step raises the pixel values to the power of the gamma value. For example, if the gamma value is 2.2, a pixel value of 128 would be encoded as 128^2.2, resulting in a lower value.

- Gamma compensation:The gamma encoding process compensates for the non-linear response of camera. It “flattens” the darker areas of the image, making them appear brighter and more detailed while compressing the brighter areas to align with its display perception. So, the image appears visually accurate, with proper contrast and detail.

- Gamma decoding:Before displaying or processing an image, it must be decoded by applying the inverse gamma function (raising the encoded values to the power of 1/gamma). This step reverses the gamma correction, ensuring the image is displayed or processed with the intended luminance.

Gamma Correction Graph

Gamma Correction Graph

Impact of gamma correction on embedded vision systems

Reliable Imaging Uniformity

Embedded vision systems deal with a wide range of image sources and displays. Gamma correction helps achieve perceptual uniformity, so images and videos appear consistent and natural to the camera across devices and lighting conditions. Without gamma correction, images can appear too dark or washed out, leading to inaccurate visual representations.

Improved Contrast & Detail

For vision systems in surveillance, automotive, and industrial automation, the ability to detect and analyze image details is extremely important. Gamma correction optimizes the contrast in images, revealing subtle details in both dark and bright areas. It can be a game-changer for accurate object detection, recognition, and tracking.

Color Accuracy

Embedded vision systems require accurate color reproduction for applications like quality control, medical imaging, and color analysis. Gamma correction is an integral part of color correction processes, enabling colors to be accurately represented. It is crucial in fields where color accuracy is critical, such as medical diagnosis or quality control in manufacturing.

Consistency of Display

Vision systems output the data to various devices, including monitors, screens, and projectors. Gamma correction helps calibrate the output to match the specific characteristics of each display, ensuring that the images and videos are displayed accurately. Hence, it is useful for systems where precise visual feedback or human-machine interaction is required.

Intelligent Image Processings

Image processing and computer vision algorithms have become the driving force behind cutting-edge embedded vision systems. Gamma-corrected images provide a more reliable basis for such algorithms, improving their accuracy in mission-critical tasks.

Adjustable to Lighting Conditions

Vision systems are often used in dynamic environments with changing lighting conditions. Gamma correction helps images maintain their perceptual consistency even as the lighting conditions shift, making the systems more reliable.

Adherence to Compliance

In the world of embedded vision, adherence to industry standards and regulations is non-negotiable. Gamma correction is a requirement in these standards to ensure accurate and consistent visual data representation.

It is clear that gamma correction is important in embedded vision systems, but it also presents several challenges that need to be addressed to achieve accurate, consistent image quality.

4 challenges of gamma correction

- Lack of standardization of gamma values: There is no one-size-fits-all gamma value that works for all systems since the choice value can vary. Of course, using the wrong gamma value can result in an incorrect image display.

- Inconsistent handling of gamma correction: Different systems and software handle gamma correction differently, which means that ensuring consistent correction across the entire workflow can be challenging.

- Limited processing power: Many systems have limited processing power and memory. So, implementing gamma correction for high-resolution images and video streams can strain system resources.

- Complex calibration: Calibrating a system to ensure that gamma correction is applied correctly to match the display device can be complicated and time-consuming, especially across lighting conditions.

e-con Systems – a pioneering leader of custom OEM camera solutions

e-con Systems has 20+ years of experience in designing, developing, and manufacturing OEM cameras. One of our USPs is the ability to customize camera solutions to fit the exact needs of the clients, no matter the type of embedded vision system they are looking to build. We also understand that image processing plays a vital role in ensuring the end image quality. Our team of experts ensures that every step can be taken to fine-tune processing, including gamma correction.

If you are looking for help integrating cameras into your products, please write to us at camerasolutions@e-consystems.com.

Visit our Camera Selector page, where you can explore our complete product portfolio.

Prabu is the Chief Technology Officer and Head of Camera Products at e-con Systems, and comes with a rich experience of more than 15 years in the embedded vision space. He brings to the table a deep knowledge in USB cameras, embedded vision cameras, vision algorithms and FPGAs. He has built 50+ camera solutions spanning various domains such as medical, industrial, agriculture, retail, biometrics, and more. He also comes with expertise in device driver development and BSP development. Currently, Prabu’s focus is to build smart camera solutions that power new age AI based applications.